Eric Parteli

Universität Duisburg-Essen, Germany

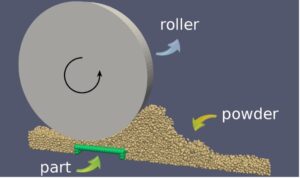

In this talk I will present insights into the physics of dry cohesive granular materials from DEM simulations. Such materials play an important role in various technological processes, such as in additive manufacturing. Moreover, dust-sized particles cover the surfaces of Earth, Mars and other celestial bodies of our solar system, thereby exerting profound impact on the geology, climate and geochemistry of their physical environment. However, the representation of dry cohesive particles and their interaction with each other in DEM simulations is still matter of research. As I will show in my presentation, DEM models should consider non-bonded attractive (van der Waals) particle-particle interactions. Neglecting these non-bonded interactions or considering adhesive potentials only at particle-particle contact may lead to incorrect numerical predictions of fine powder behaviour. I will show that it is possible to reproduce quantitatively the packing fraction of strongly polydisperse powders made up of spherical particles as a function of average particle size, provided that the full particle-particle interaction model – including contact and non-bonded attractive van der Waals forces – is considered. Moreover, DEM simulations using this model reproduce quantitatively observed values of the angle of repose from a comprehensive set of experimental measurements, for particle sizes ranging from the micrometre- to the centimetre-scale. Inspired by this quantitative agreement, I obtained an expression for the angle of repose as a function of the Bond number (the ratio of the cohesive force to the gravitational force). As I will show, this expression is simple and further reproduces the angle of repose from numerical simulations within the broad range of gravitational acceleration values from 0.06 to 100 times that of Earth. The future application of this model has the potential to improve the assessment of powder mechanical behaviour for additive manufacturing. In my talk, I will present a DEM model for the powder application process in additive manufacturing that incorporates a representation of complex particle geometric shapes. However, consideration of non-bonded van der Waals interactions is indispensable to reproduce the observed powder behaviour, as I will explain in my talk.